The MultiProf®

enclosure concept

Aluminium enclosure systems

Our service

If you let us develop, produce or finish your products - whether single components or complete assemblies - you can improve your economic efficiency because you save investments for plants, workforce, know-how and environmental protection. Additionally, your flexibility increases and placing complete orders the time-consuming coordination of different suppliers is omitted.

Among other things the following services make part of our all-round service package

Consulting and construction

The realisation of customer's wishes regarding functionality, design, quality, safe...

...ty and costs is as well task of the construction team as the development of new approaches and ideas according to the requirements for a product to be created. We support the customer from the first idea to prototyping and sample production until series maturity with our know-how.

Documentation and after-sales service

You can still order all front panels, enclosures, foil keyboards and input devices have ever been de...

...livered since 1993 at the final delivery status today. If there are old components included we will develop a new one due tu our slogan "form - fit - function". Our products are characterized by long-life availability.

Mounting and assembly

We mount and assembly mechanical and electronic components to as...

...semblies or complete devices and systems.

Procurement of components

We procure the necessary components for you and proof them according to (specific) re...

...quirements. Benefit from our long lasting experience in the assessment of visual characteristics. Especially when it comes to the selection of surfaces, glass panels or displays.

Logistics and packaging

Our gripping ideas are really not cardboard!

Depending on quality, form and size we package your pro...

...ducts carefully and develop suitable packaging concepts that protect from possible damages during the transport and in the further processing.

The perfect transport

In order that your product arrives its destination on time and undamaged we provide all necessary do...

...cuments for national and international transport, order a fitting logistic company and track the transport until arrival. On request we also offer a special delivery service.

Express service

A new product must be brought to market maturity as quickly as possible. We offer a func...

...tioning express service, which is unique in this form in this industry, i.e. guaranteed delivery within 5, 10 or 15 working days for all the production areas.

Digitisation accelerates many business processes. Your customers always expect shorter reaction and delivery times. For this purpose, the Wöhr express service modular system offers a fast and reliable solution through its five modules.

Important facts

- Very high proportion of in-house production

- Extremely versatile production options

- Top-class machine equipment

- Regular multi-shift operations on up to 6 days a week

- Highly motivated and experienced employees

- And many more

Module 1: free choice in the Wöhr portfolio

Only we offer this high-speed service. It is available across our complete service portfolio: Input sys...

...tems, enclosure construction, mechanics, surface technology and systems engineering.

On top of it, it is available beyond prototypes. Talk to us and we will find a solution, no matter how complex your project is. The Wöhr express service modular system covers everything: from simple, individual production steps to the development of customer-specific system solutions.

Module 2: Choose the time frame

In the Wöhr express service modular system, you can choose between the de...

...livery times of 5, 10 or 15 working days for products from all (!) production areas, as well as their combinations. After checking the technical and scheduling feasibility, you will receive a fixed, binding delivery date. Where else do you get so much planning security? In some areas, e.g. painting or powder coating, delivery times of up to 6 hours are possible as soon as we have technical clarity. If purchased parts such as printed circuit boards, special housings/materials, etc. are planned, an express service order depends on the supply or provision situation.

Module 3: Make the most of our versatility

As far as possible, we rely only on ourselves so that you can count on us: Our un...

...usually high proportion of in-house production and our flexible, state-of-the-art technical equipment allow us to handle your urgent projects in-house. This is because we have most of the processes and production technologies for keyboards and touch screens, systems engineering as well as mechanics and housings including surface technology, glass production and assembly - i.e. for a wide range of applications.

Module 4: Rely on our flexibility

Flexible production planning, motivated employees and decades of experience in express services are the ba...

...sis of our express service modular systems. These are supplemented with our extremely versatile production options. The last, but not the least, our regular multi-shift operations on up to 6 days a week enable us creating additional capacity for processing express orders.

Module 5: Trust in highest quality

For express service modular systems, the typical Wöhr quality has utmost priority: Each ex...

...press order is produced under series conditions and passes through the production processes highly efficiently thanks to the proven project management and our experienced and motivated employees. Our commitment to a maximum reliable express service is based on an organically grown understanding of services which is an integral part of our daily lives. We can also find a high-speed solution for you - with a delivery time of 5, 10 or 15 days.

Most recently since the Corona crisis, we have all come to know and appreciate the possibilities of online communication. The live exchange also has a number of advantages for our cooperation with customers and interested parties. We are happy to provide you an overview of this here.

People can see each other – there is much to be said for it

A web conference with your contact persons at Richard Wöhr GmbH usually turns out to be more suc...

...cessful than a lot e-mails or telephone calls. We have technically optimal video conferencing facilities at our disposal, with which we can bring together all relevant specialists for you in a personal meeting. With a sharp picture and good sound, data and drawings can be assessed on a common screen and the advantage of a quick hand-drawn sketch can also be fully put to use online.

Gathering competence

Both for us and for you: In a web conference, experts from different fields can move a pro...

...ject ahead together. With us, these are, for example, project managers, business persons or experts from the mechanical and electronic field. On the customer side - i.e. on your side - all internal participants (e.g. the purchase department, technicians, ...) can also participate without everyone having to invest a lot of time on the go.

Modern and efficient

From initial contact to negotiations and clarification of technical details: modern tech...

...nology allows the quickest possible exchange, immediate clarification of questions and direct explanation of current offer constellations. We are glad to always be available for you, and the live presentation of products in our showroom is possible as well.

Quick exchange

With an online conversation, you and we can save a lot of time that would otherwise be wasted on or...

...ganisation and travel. This time advantage can be put to good use for your project! Together we can find the right offer faster, start the production earlier and deliver quicker.

Less travel stress and more CO2 savings

Supported by advancing digitalisation, we are able to avoid unnecessary business trips. A video con...

...ference therefore makes a lot of sense. And there is an additional benefit that will become the focus of a lot of attention in the coming years: With online meetings, you and we can effectively reduce the CO2 footprint of our products and our company that is caused by business travel.

The next steps

We would clearly appreciate it very much if we could increasingly conduct our business relation...

...ships via the medium of video conferencing. Your contact persons at Richard Wöhr GmbH will always offer you this option. Nevertheless: We would like to meet you in person in the future as well!

TeamWÖHRken Sie mit uns!

You can arrange a video/web conference by clicking on the button "callback".

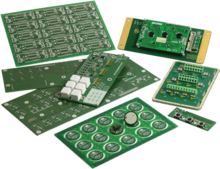

We are your competent partner for the following services and beyond

Often the target for a lot of purchasers is to reduce their number of suppliers to save expenses for administrative effort.

The Richard Wöhr GmbH offers more service and a higher added value by covering more products and services under one and the same roof.

In this case for our customers “outsourcing” means converting high fixed costs into lower variable costs. Using our services doesn’t only involve financial advantages like a lower investment need and decreasing operating costs, but also an improvement of the service quality and an increase of the adherence to schedules – especially because of our express service.

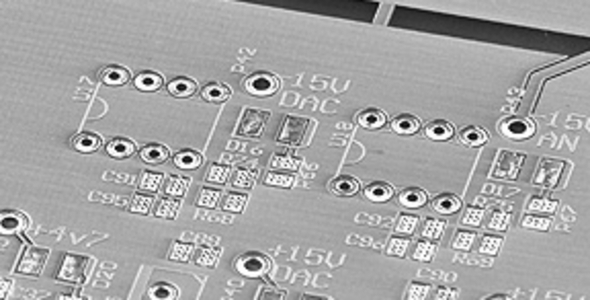

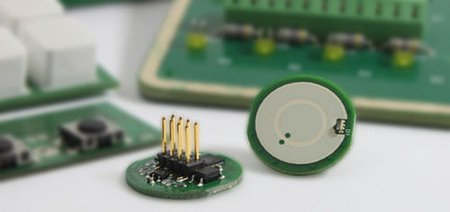

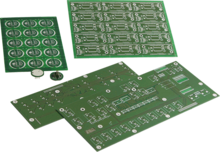

The first step during the process of SMD assembly will be realized by our fully automatic soldering paste printer. The soldering paste printer is able to take printed circuit boards with a size of 530 x 530 mm. Vector and gerber data can be provided by the customer or will be generated by our development.

With our fine pitch pick-and-place machine we are able to edit and SMD assemble printed circuit boards with a size up to 500 x 350 mm. Our SMD assembly machines has an integrated glue dispenser. The assembly of printed circuit boards is possible from the component size 0603.

In the final step during the SMD assembly the printed circuit boards will be soldered up reliable with a vapor-phase soldering system. The vapor-phase soldering system is suitable for pcbs with a maximum size of 500 x 350 mm, but because of the vapor-phase soldering system tooling dimensions only printed circuit boards with a size of 500 x 350 mm can be SMD assembled.

The maximum size for a completely SMD assembly of pcbs is 500 x 350 mm.

You can also benefit from the flexibility of the Richard Wöhr GmbH in the THT assembly sector. We are able to respond quickly to special customer wishes without having you pay high preproduction costs. The specialty of our house is small and medium...

...-sized series to a great extent.

Our selective soldering machine runs exclusively with lead-free solder (RoHS-conforming) and operates with 99,999 % nitrogen. The overall dimension of the machine’s mask is 500 x 500mm, but it’s only suitable for the reception of printed circuit boards with a maximum size of 460 x 460mm.

Because of technical and economic reasons not on all components will be worked on by using a machine. Some boards in our THT assembly will get finished manually (hand soldering and depanelization).

The different components and the finished parts will be mounted and checked in the module- and housing assembly which is an ESD protected area. We guarantee a highly process safety and a short processing time which is possible because of our intern organization structure. The Richard Wöhr GmbH knows nearly no limit regarding the flexibility and the number of varieties.

The installation and the vernier adjustmentof mechatronic components which is made with our own Wöhr components or with customer’s components, takes place in specific shown ESD – protection zones, ESD –...

... protection workplaces as well as in cleanrooms.

Our range of services includes in particular:

- Touchscreen integration

- Display assembly

- Software installation

- Complete wiring and marking

- EMB – board installation

- Peripheral device connection

- to industry requirements geared core structure e.g. hygienics right, MPG-conform, EMC

In terms of optical inspection, functional testing and final testing the Richard Wöhr GmbH offers in addition the following services:

- IP protection tests

- EMV tests

- CE certification

- Editing manuals/documentation

- Change of climate tests

- Chemical resistance tests

- Shock tests/vibration tests

- Lifetime tests

- Logistics concept

- Printed circuit boards test

- Optical test

- Functional test

- Final test

"There we have the spaghetti syndrome!" That has now been surpassed!

Because we attach great importance to a well-functioning, secure and reliable connection between electronics and application.

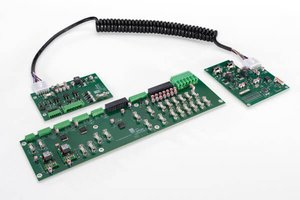

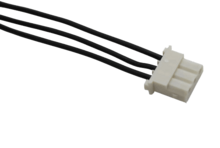

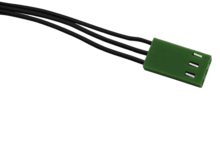

We assemble cables of all kinds (hook-up wires, strands, round cables and ribbon cables) in-house and take over also the laying and mounting together with the electronic components or the wiring of assemblies up to the inspection.

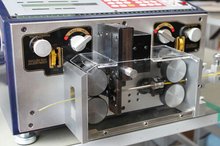

Cable assembler

Cables from the roll are brought in-house to the desired size by means of a cable assembly, even in great series. By means of this device cables up to the outer diameter of 8 mm (6 mm² area diameter) can be quickly and reliably cut and isolated. Wöhr® assembles also the suiting grounding cables from the own production for the installation in industrial keyboards and mounts them product- and application-specificly.

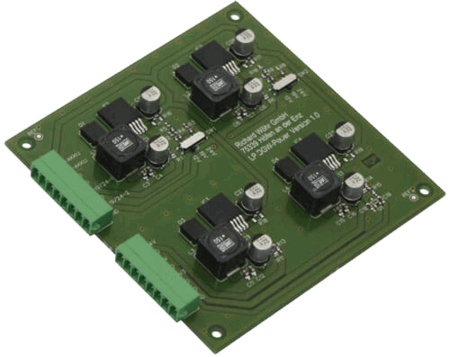

Customized 4-way DC / DC voltage converter

- Input voltage 25-30V

- Output voltage 1x 5V/4A,

1x 12V/4A, 2x 12,19,24V/4A

selectable via microswitch - Residual ripple oft he output voltage

- Efficiency >85% @28Vin

- Size 100x100 mm

Build in SMD design for mounting on an aluminium carrier board to realize a passive cooling (without fan)

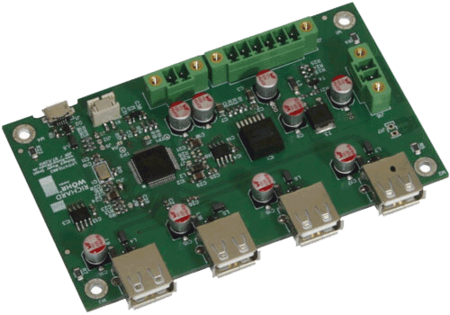

Active 4-USB Hub 2.0 with high-speed (480Mbit7s)

- supply voltage with 12 V

- UPS battery can be connected thus uninterrupted operation

or mobile application possible - Master-Slave principle (If a USB master is plugged in at the input

(5V are detected) the voltage of the outputs is switched on)If the master switches off or is pulled, the slaves become switched off - additional + 12V output

Do you need support in the area of development?

Here you will find our comprehensive range of services in the field of development

Layout service

- CAD/data import

- Data preparation

- Layout preparation

- Use construction

Software development

- High level language programming

- Embedded programming

Hardware development

- Concept preparation

- Component selection

- Circuit design

- Test conception

- Manual editing

- Enclosure development

- Front plates

- Assembly parts

Tests and analyses

- Feasibility studies

- Validation

- Cost analysis/budget vs. product + development

- Test planning

- Tests

- Documentations

![[Translate to English:] RMA-Nummer anfordern [Translate to English:] RMA-Nummer anfordern](/fileadmin/_processed_/a/7/csm_rma-nummer-woehr-s_047446a05c.png)

To speed up the process of repair or complaint, we kindly ask our customers to request a RMA (Return Material Authorization) ID, before send us the devices back.This helps us to optimize this process.

To obtain a RMA ID please fill out the form below as good as possible. Required fields are with anasterisk (*) indicates. We reserve repairs without an RMA number to reject.

Using the RMA-Number

1. You find a defect on our product.

2. Please use the following link to ask for a RMA Number

3. Please fill out the form there and send it via click to us. (All fields marked with an asterik * are required).

4. Our service team will be notified and you`ll get your personality RMA Number via E-Mail.

5. Please mark the RMA Number clearly visible on the transport packaging and the delivery note. Send the defective product back to us or we will have it collected by our parcel service.

6. After receiving the defective product, our service team will check it and will get in contact with you

7. Thank you for comply with the above mentioned process. You will help us doing this process smoothly.

Date: 26.01.2015

Contacting us

You have the option to contact us using a contact form on our website. In this case, the details provided by the user are saved for the purpose of communicating with them. They are only shared with third parties for the purpose of transmission to Wöhr. They are not shared in any other way.

The processing of the data entered into the contact form is therefore exclusively based on your consent (Art. 6 (1) lit. GDPR). You can revoke this consent at any time (see rights of the person concerned, see privacy policy).

The data entered by you in the contact form remain with us until you ask us to delete or revoke your consent to the storage. Mandatory statutory provisions - especially retention periods - remain unaffected.

Do you have any questions or problems with one of our products? Or you need an update or upgrade for your system? Then please take a few minutes to fill out our support form. This will help us to answer your request quickly and efficiently.

Thank you for your friendly support!

Contacting us

You have the option to contact us using a contact form on our website. In this case, the details provided by the user are saved for the purpose of communicating with them. They are only shared with third parties for the purpose of transmission to Wöhr. They are not shared in any other way.

The processing of the data entered into the contact form is therefore exclusively based on your consent (Art. 6 (1) lit. GDPR). You can revoke this consent at any time (see rights of the person concerned, see privacy policy).

The data entered by you in the contact form remain with us until you ask us to delete or revoke your consent to the storage. Mandatory statutory provisions - especially retention periods - remain unaffected.

We are happy to assist!

+49 7081 9540-0 | Richard@WoehrGmbH.de

WÖHR sectors in one click